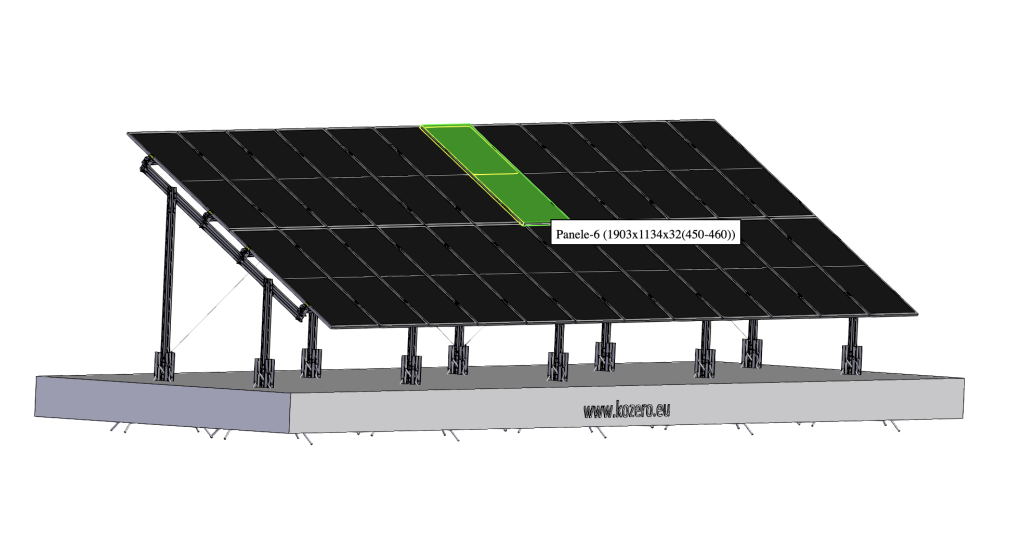

3D virtual model

36° angle for Lithuania

LT dažniausiai montuojamos konstrukcijos pagamintos ir skirtos Lenkijios (30°) ir Vokietijos (25°) rinkai.

Lithuania is located further north, so the optimal tilt angle differs from our neighbors. Mathematically, the most optimal angle is calculated to be 36 degrees..

We manufacture the structure with a 36-degree tilt angle. hence our slogan 'Made in Lithuania and tailored for Lithuania.

14% stronger construction

Constructions most frequently transported to Lithuania are from Poland. They are made from C-profile, which is commonly used in the construction industry and has been adapted for the production of solar power plant structures.

Our engineers assessed the resistance to bending and twisting of the C-profile and concluded that it is not the most optimal choice for a solar power plant structure.

By using the same amount of material, we have created a more advanced SIGMA profile. It is approximately 14% more resistant to bending loads and even approximately 23% more resistant to twisting loads.

Computer simulations and physical tests were conducted at Kaunas University of Technology (KTU).

By using the same amount of materials, we can offer a stronger construction for the same price.

No heavy machinery needed

No heavy equipment is needed for the construction.

Adjustable diagonal strips are used for ground anchoring.

They are driven into the ground with a simple rotary hammer. This way, we avoid the use of heavy machinery, which is expensive and can damage the existing yard environment.

High-quality material

The construction is made of the highest quality galvanized steel. (Prime galvanized Low Carbon steel DX51D Z330 according to EN-10346)

According to EU and LT construction standards, steel with a 275 g/m2 (23 microns) zinc coating is used everywhere, which comes with a warranty of up to 25 years.

On our part, we use a zinc coating of 330 g/m2 (approximately 25 microns thick coating), which is 20% more zinc in terms of quantity than required by regulations.

For example, take a look at the old (Soviet-era) apartment building facades, which haven't rusted in over 40 years.

Metal thicknesses

The structure has 2 variants. They differ in metal thickness.

Version 3.0 / 2.0 / 2.0

- Supporting legs made of 3mm metal

- Crossbeams made of 2mm metal*

- Longitudinal beams made of 2mm metal*

Version 3.0 / 2.0 / 1.5

- Supporting legs made of 3mm metal

- Crossbeams made of 2mm metal*

- Longitudinal beams made of 1.5mm metal*

Calculated using Construction Technical Regulation No. STR 2.05.04:2003 'Effects and Loads'.

*Prime galvanized Low Carbon steel DX51D Z330 according to EN-10346

Experienced installers can assemble a ground-mounted 10kW solar power system structure in approximately 5 hours.